The demand for land for housing and business development in South Africa is a demand that never slows down. Recently when a local municipality at Ikageng in the North West Province set aside stands for development, they realised they had to reduce the 100-year flood line and take preventative measures to reduce the possibility of stormwater or flood damage to this marked area. Technicrete’s Armorflex proved to be the most effective and sustainable option to meet their requirements.

“The project was initiated after it became apparent that some residential stands were set out within the 1:50 year flood line. The formalisation of the trapezoidal channel to contain the 1:100-year flood meant these stands would be available for development. The construction of the lined channel could increase the capacity with a smaller cross-sectional area” said Dries Joubert, Design Engineer from FHP Consulting Engineers on the Ikageng project.

Technicrete’s internationally licensed Armorflex 180 was recommended as the best option for the Ikageng project from the range of Armorflex products Technicrete manufactures and supplies. The 180 is an open block suitable for stormwater and drainage channels, erosion control, roadside drains, striproads and access roads.

“We originally thought that a combined concrete and concrete filled geo cells type lined canal would serve the purpose, but due to poor soil conditions which required substantial earthworks Armorflex was a preferred option and offered a reduced construction period mainly because of the interlocking pattern which offered flexibility should settlement occur” added Joubert.

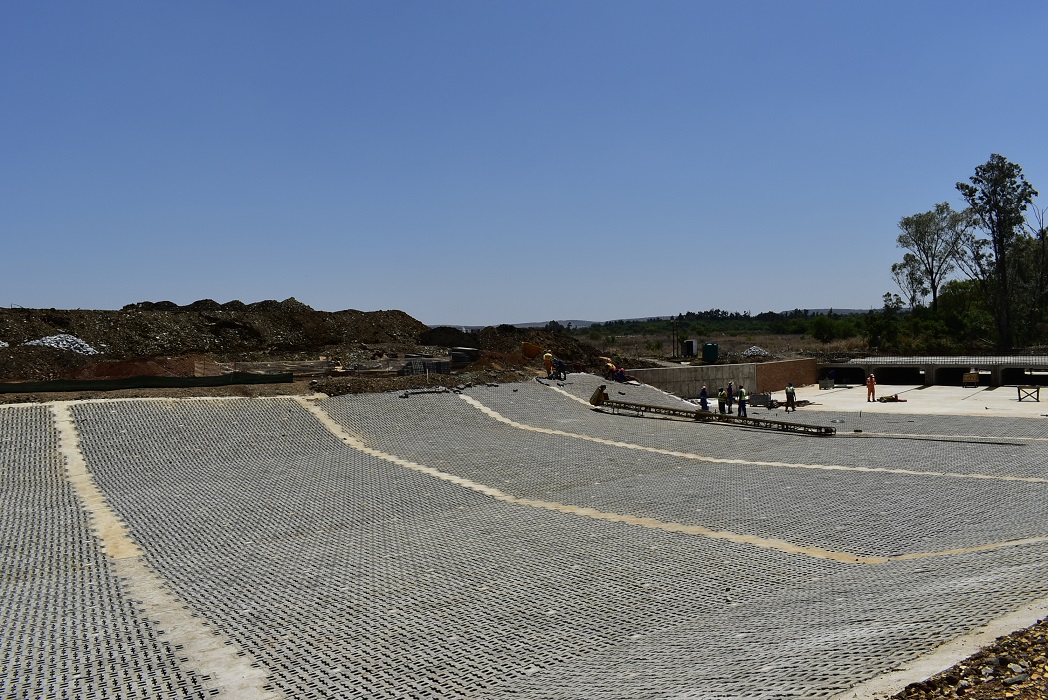

The channel had a natural alignment, and the Armorflex improved the natural flow characteristics of the channel during flood conditions, hence its gently curved installation which eliminates the small radius bends that could have created overtopping.

Armorflex 180 blocks are tied to adjacent blocks with galvanized wire to form long mats. As and where required, Armorflex can also be anchored into in-situ soil to further assist with stabilisation of the blocks and mat in general. The Armorflex 180 blocks provide a loose but sophisticated interlocking design allowing the surface to remain flexible to movement without the cracking and spalling issues that occur with insitu cast concrete when exposed to regular stormwater or flooding incidents.

The Armorflex 180 blocks offer a perfect lining for drainage channels. At aprons at pipe inlets and outlets, Armorflex eliminates pipe undercutting that can lead to severe problems such as surrounding bank failure and hence additional siltation downstream.

Joubert added “We always try to utilise local labour where possible, and the Armorflex product lends itself to this objective, enabling us to upskill at site and create employment opportunities down the line”.

One of the challenges on site at Ikageng was ground water seepage which impacted upon the delivery of project products, Anton Muller, Managing Director of Born Free Civils, a contractor at the Ikageng project commented “Due to water seeping from underground at the project site, resulting in a majorly wet and muddy surface, we built a temporary roadway so that Technicrete could deliver the daily quantity of 1000 m2 Amorflex blocks that was required”.

In order to beat the summer rainfall, approx 40,000m2 of Armorflex was placed in only 3 months. The channel profile had been prepared previously such that the installation team needed to finalise and smooth out levels, place geofabric and Armorflex, wire up the system and backfill. This was a mammoth task in scale, to achieve in such a short period of time but it proves the versatility of Armorflex.