Technicrete, one of South Africa’s leading manufacturers of precast concrete products turns 50 this year. Originally part of the Concor Group launched in 1948 by Jurgen Schultz, who, in 1968, saw a gap in the market for the manufacture and application of precast concrete products. The group launched Concor Technicrete as a new division that would focus totally on this new range of precast offerings.

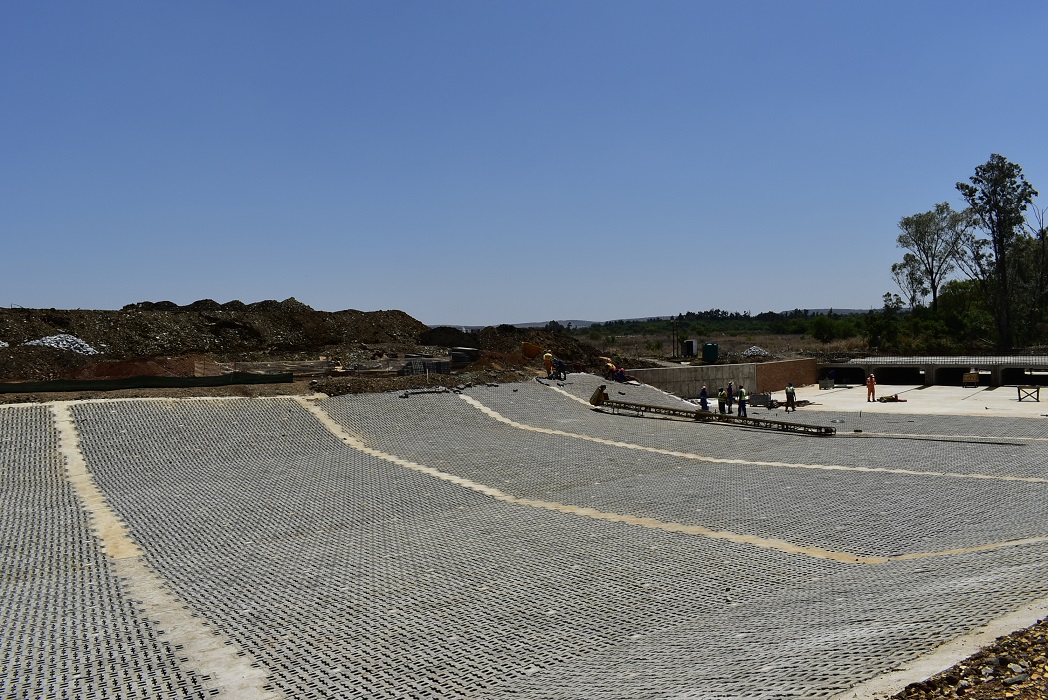

So strong was Schultz’s belief in the precast market that he obtained exclusive rights to manufacture Deckwerk blocks in South Africa, which were used in the successful construction of the Magoebaskloof, Fanie Botha and Bloemhof Dams all of which were lined with these purpose design blocks from Technicrete. The success of Concor Technicrete products on these projects is what established the division as a major industry player.

Following on this success they received a contract to line a canal from the Kukane River in the then called Ovamboland (now Northern Namibia) to Oshakati. Fifty years and thousands or projects later, the rest, is as they say, Technicrete history.

Past and Present

In 2006, Concor was acquired by Murray and Roberts and Concor Technicrete became an independent company within the group. This resulted in the name change to simply Technicrete, an iconic brand that has stood the test of time.

In 2013, The Infrastructure Specialist Group (ISG) was formed after Murray and Roberts unbundled Technicrete, Rocla and Ocon Brick who joined the ISG Group. A new executive team for ISG was established, led by Albert Weber the current Chief Executive Officer (CEO).

Weber commented “The Technicrete brand is iconic in South and Southern Africa. It is known for quality products that have been manufactured using the latest available technologies backed up by a superior plant workforce and sales team. To celebrate Technicrete’s 50th birthday is a major milestone in our history as a company and in my role as its CEO. I am extremely proud of how Technicrete is still considered a preferred supplier to most commercial and residential projects of all dimensions, and how it has grown to meet the often-stringent requirements of our ever-changing times”.

Over the last 50 years, Technicrete has grown operationally as well as product wise. From small beginnings to the construction of Technicrete’s first major plant at Randfontein, the establishment of nine other country-wide manufacturing facilities followed. The product range too has expanded from Deckwerk to a catalogue that offers a complete range of precast concrete pavers, kerbs, erosion protection systems, drainage, retaining walls and concrete masonry solutions that has applications for both commercial and residential developments.

Technicrete Values

“Our people are at the core of our success. Without their commitment to our brand and customers we would not be here 50 years on. It is our people who live our core values that embrace: care, respect, integrity, accountability and commitment to the delivery of quality products and services” said Weber.

“We are committed not only to the continued upskilling of our own staff, but also to the upliftment of local workforces through knowledge transfer in areas where we supply or manufacture our products. We wish to make a meaningful contribution to the infrastructure and people of this country” said Weber.

Technicrete has supported various educational and community support-based organisations over the years through its Corporate Social Investment Programme.

Technicrete operates a STOP.THINK philosophy and commits itself to providing a safe and healthy environment for its employees with an objective of ‘Zero Harm’ at all its sites.

Certified Standards

Technicrete is a fervent member of the Concrete Manufactures Association (CMA) in South Africa and adheres to the ISO 9001:2015 Quality Management System.

Despite congestion within the precast concrete product market, Technicrete has, based on its history, always had the edge, unique attributes of the company include:

- A strong historical foundation which allows us to build upon our trust marks of heritage and credibility

- Delivery on key promises of quality and product service, for which we are highly respected

- A depth of knowledge based on the experience we bring to the business place and customer base

Products to suit all requirements

From major civils projects to medical facilities and universities; residential upgrades to upmarket residential estates; motor vehicle dealerships to large commercial buildings and shopping complexes; infrastructural projects to health clubs, Technicrete has been involved for 50 years in these types of projects around South and Southern Africa.

Weber said “In 1978, the Aggeneys mining township was established in the Northern Cape, the Technicrete Zig Zag Block Pavers are still there in good working order nearly 40 years later – that’s good quality product for you”.

The Future

“Technicrete will continue to play a major role in the supply of precast concrete products as infrastructure around the country continues to be upgraded. Private sector commercial and residential property developments still reflect as a growth industry and I believe our service, competitive pricing and product quality will continue to give us the edge making us a preferred supplier for at least the next 50 years” concluded Weber.

In 1978, the Aggeneys mining township was developed in the Northern Cape by the then Black Mountain Group. Housing and roadways were built for the groups` employees and local residents. Technicrete, then known as Concor Precast, operated two block manufacturing plants adjacent to Aggeneys enabling them to produce the newly designed Zig Zag block pavers for the project.

In 1978, the Aggeneys mining township was developed in the Northern Cape by the then Black Mountain Group. Housing and roadways were built for the groups` employees and local residents. Technicrete, then known as Concor Precast, operated two block manufacturing plants adjacent to Aggeneys enabling them to produce the newly designed Zig Zag block pavers for the project.

Upmarket residential estates like Broadlands Estate in Polokwane require residents to ensure that any additions or refurbishments done to their properties conform to the high- existing standards. Aesthetics and finishes have to reflect the lifestyle that owners have invested in, and Technicrete paving is considered to be the leading choice when it comes to paving at the estate.

Upmarket residential estates like Broadlands Estate in Polokwane require residents to ensure that any additions or refurbishments done to their properties conform to the high- existing standards. Aesthetics and finishes have to reflect the lifestyle that owners have invested in, and Technicrete paving is considered to be the leading choice when it comes to paving at the estate.