The effective management and subsequent attenuation or storage of stormwater has never been more critical in South Africa than at present. For many local municipalities, submission of stormwater management plans is compulsory with all proposals for new commercial and residential developments.

Municipalities and Engineers alike are trying to reduce the load on existing, traditional stormwater networks, as these are falling behind in their effectiveness due to massively increased volumes of water caused by the developmental impact of replacing grassland with hardstand.

Sustainable Urban Drainage Systems (SUDS) and subsequent engineering design, start with the intention of creating newly developed sites that mimic their pre-development state by virtue of majority of stormwater not running off the site but rather infiltrating into the ground and thereby replenishing critical below grade water tables and aquifers. The goal is to manage stormwater on site and have as little as possible passing into municipal systems.

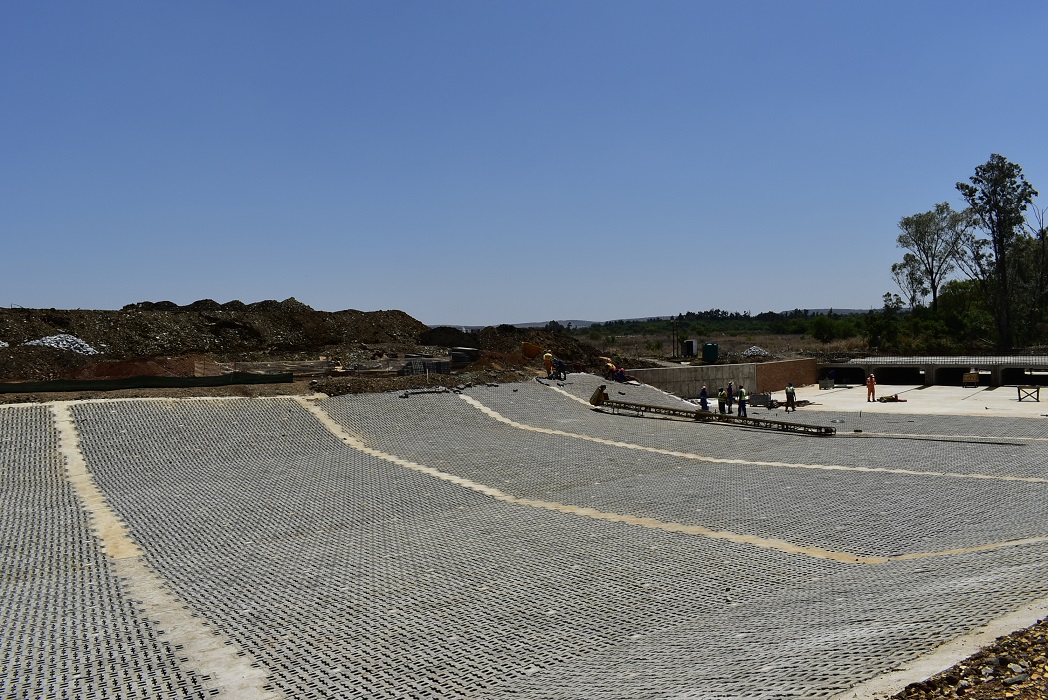

Technicrete’s “Aqua” range of blocks, manufactured to national standard: SANS 1058-2012, subscribe to a form of SUDS known as Permeable Paving whereby vertical ‘slots’ between adjacent pavers provide drainage channels allowing stormwater to flow from surface, through the paving layer, into suitably designed layerworks below. The premise behind a permeable paving system is such that voids, inherently present between stones (19mm – 63mm) making up the structural layerworks of the pavement, can accommodate water capacity up to 25% of the volume of these layers.

A general design consideration for the paving block is to allow water to flow through this layer at a rate of approximately 9000 liters (9000mm) per m2 per hour. A geotextile placed between the bedding and storage layers will have the effect of throttling this flow through rate to approximately half, or 4500 liters (4500mm) per m2 per hour, although at design stage of the overall system, one generally uses a rate of 10% of the maximum, namely 900 litres (900mm) per m2 per hour as this allows for up to 90% potential blocking up of the system over time. Accordingly, a heavy rainfall event can be designed to be managed such that the entire volume of water is maintained and managed within the site boundaries.

A secondary consideration at this stage of design is whether to capture this water only for attenuation (slow release) or retention and re-use, both of which offer a myriad of further options. As such, three basic design philosophies prevail, namely a full infiltration system, a partial-infiltration partial-discharge system or a ‘tanked’ storage system.

A full infiltration system is underlaid with a pervious geotextile and is suitable for use where it is feasible to infiltrate stormwater directly into a suitable subgrade.

A part infiltration – part discharge system enables attenuation into the municipal network at the rate prescribed for the site as well as infiltration into the ground below.

The third option is that of a tanked system which is lined with either LDPE or HDPE impervious membranes to create a ‘tank’ and thereby capture and store the water for reuse in grey water and irrigation systems. With additional treatment, this stored water could be made available for potable use. In some instances, the impervious membrane is required to restrict water from entering the subgrade and thereby preserve structural integrity of this layer. This could be an important factor where clay subgrades are encountered, in dolomitic areas or where soils / storm-water are expected to be contaminated.

An additional advantage of permeable pavement design is the element of contaminant treatment. Studies have shown that heavy metals, including but not limited to, Cadmium, Copper, Lead, Nickel and Zinc are partly removed from the water through percolation in the stone layerworks such that water flowing out of these systems is within potable requirements for these metals. Hydrocarbons (Oil) has also been seen to be broken down by micro-organisms that grow in the geofabric and other layers that are generally kept moist.

Technicrete’s Permeable Paving systems have been successfully applied in various developments, including major industrial factories and large campus parking facilities and should be both the client and designers preferred system for prevention of run-off and flooding. These systems are ideally suited for installation in car parks, industrial estates, retail centres, pedestrian areas, domestic estate drives, freeway services, garages, truck stops, container terminals and other heavy-duty applications and can be installed at almost any installation where traditional segmental concrete block paving has been specified.

As with all Technicrete products, our in-house engineering team is always available to advise and assist with designs in this regard.